Company

Large Automotive Manufacturer

Industry

eMobility

The automotive industry is on its way to an all-electric future, and auto manufacturers are quickly adding new electric vehicles (EVs) to their lineups. One leading manufacturer turned to ATS Industrial Automation as its automation partner for modular EV battery cell assembly and test automation solutions to meet the demand for EVs.

As the auto manufacturer reinvents itself as an electric vehicle manufacturer, a lot is at stake, and battery assembly is critical. The battery technology is evolving quickly, with design changes happening weeks before launch. As battery costs decline, superior manufacturing automation processes are critical to maintaining margins. With the aggressive production targets, schedule manufacturing needs to ramp up fast. In addition, manufacturers need to leverage current real estate; building a new plant can add millions of dollars and delay critical EV projects.

“We have a long-standing working relationship with ATS Industrial Automation and are proud of the work we have accomplished implementing our strategy for zero crashes, zero emissions, and zero congestion. The EV factory launch marks the beginning of the pivot point in our vision to all-inclusive electrification.”

Engineering Group Manager,

Large Automotive OEM

The automotive manufacturer turned to its trusted automation partner, ATS Industrial Automation, to help scale its battery manufacturing. The company valued and benefited from ATS Industrial Automation’s global reach, scalability, and proven project management skills to execute projects on time and budget. Together, ATS Industrial Automation worked with the manufacturer to design and implement an innovative automotive assembly system inside a tight manufacturing schedule.

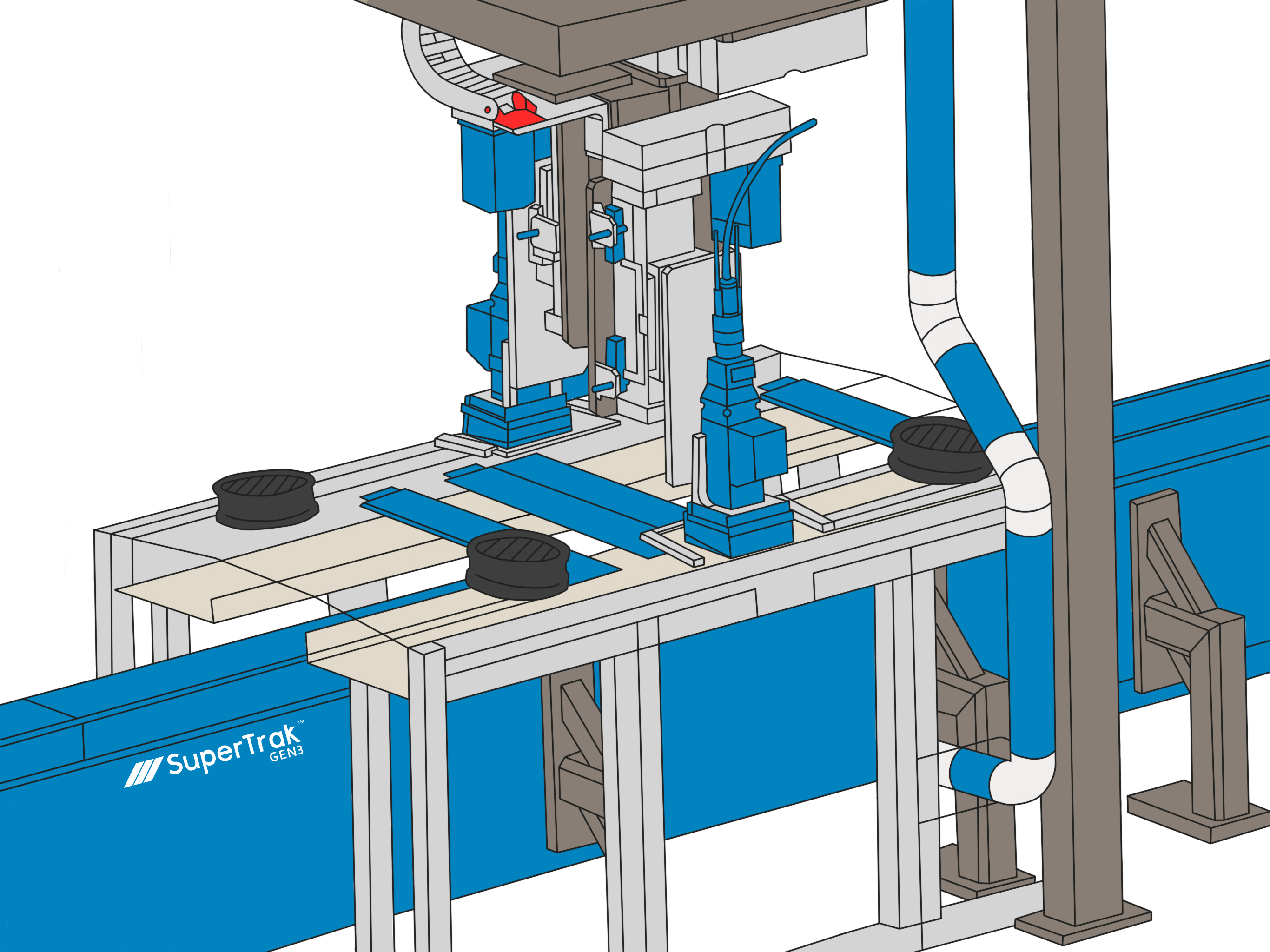

Leveraging the extensive battery knowledge of different cell types, the team developed a modular assembly system based on ATS Industrial Automation technology and product offerings. The system uses the SuperTrak CONVEYANCE™ Platform modular platform, a leading-edge linear motion system that increases throughput while reducing footprint and energy consumption. By using a modular platform, the manufacturer gained a 50% improvement in floor efficiency, maintaining their project schedule, and keeping to a budget.

SuperTrak CONVEYANCE™ Platform Over-Under Configuration

An accurate and robust laser weld is vital to the battery and serviceability of the vehicle. Modern EV battery assemblies require 10,000 laser welds or more, and one welding defect can impact a vehicle’s range by almost 2%. A strong weld creates an efficient charge and discharge of the battery. A high-quality weld can prolong the battery’s life and withstand crashes. However, welding is challenging. It’s hard to inspect failures. Welds must be done in a consistent, repeatable process. Stack them too fast, and the packs do not line up.

The ATS Industrial Automation team spent 3-years developing an innovative welding approach that accurately detects and validates the welds. By reducing any opportunity for a weld failure, ATS Industrial Automation optimized welding efficiency by 30% for the auto manufacturer, creating a reliable and repeatable process.

ATS Industrial’s SuperTrak CONVEYANCE™ Platform is the heart of battery assembly.

“Such challenging projects can only succeed when there is a trusted partner, and for 15 years, we have been working with this customer to drive innovation and collaboration.”

Udo Panenka,

President of ATS Industrial Automation

With ATS Industrial Automation as a trusted partner, the EV battery manufacturing facility can adapt to market demands and design evolutions, securing the company’s market position today and in the future. The assembly automation processes created have placed the auto company is in a position to surpass other EV manufacturers on the market.

ATS is here to partner with you to deliver benchmark processes, overcome manufacturing barriers, and streamline manufacturing. With fixed launch dates, every day, every dollar, and every resource matters. Delays mean missed revenue that impacts employees, customers, and shareholders. ATS Industrial turns today’s innovation and automated processes into tomorrow’s reality.

Efficiently, Effectively & Intelligently.

SuperTrak CONVEYANCE™ Platform

Every project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.