Digital revolution

The global pandemic has hit the construction industry hard in several ways: worksite lockdowns, supply chain disruptions, and delayed and suspended projects. Nevertheless, for many within the industry it has accelerated innovation. In years to come the past 16 months may be seen as a pivotal time, and the virus a key catalyst for change that led the sector into a much stronger and more robust future.

Breaking down barriers

There’s no doubt that the impact of the pandemic is still being felt, with projects facing ongoing supply issues, a halt in planning and inspection timetables, and new measures to ensure workforce safety. However, although the past year has been one of the most challenging in recent memory, it has presented opportunities for the construction industry to improve and overcome its historic barriers to change by forcing the incumbents to adapt and work differently. Businesses have embraced new technology to ramp up productivity and ensure work is carried out in accordance with ever evolving health and safety regulations.

Before Covid-19, many construction businesses’ processes, operations, and procedures were considered outdated, with recent events further bringing this to light. A recent McKinsey report1 has predicted big changes across the construction industry over the next decade, adding that the bulk of short and long-term pandemic-driven issues will be solved with technology. It reports that the mandate for change and technological adoption in construction has never been stronger, with the pandemic ‘only serving to provide additional urgency to the pre-existing productivity and data-visibility issues facing construction companies.’

Technology like the integration of AI and BIM to modern methods of construction is not new, but the uptake has been slow. The pandemic, however, has provided the necessary impetus for many to adopt alternatives to traditional practices and digitalisation is playing a key role. In PwC’s 23rd Annual Global CEO Survey last year, even before the disruption of Covid-19, 77 percent of engineering and construction CEOs were already planning for more 4IR operational efficiencies to drive growth2.

Key benefits of digital engineering tools in construction

Key benefits of digital engineering tools in construction1. Better communication

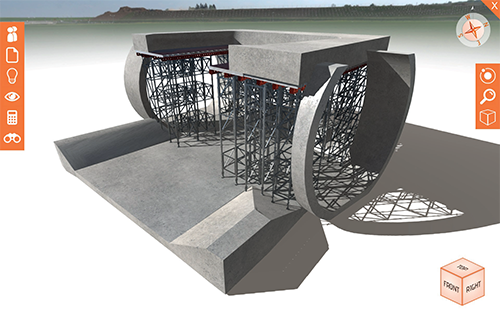

Digital solutions in construction contribute to a more inclusive construction process where the flow of information is unhindered. The latest digital engineering tools offer realistic 3D visualisations of temporary works on a build, helping to break down any communication barriers and ensure transparency across the supply chain for any specified systems. This means any potential issues can be quickly raised and remedied by contractors.

2. Winning tenders

Digital technology not only helps to improve productivity and streamline decisions across the supply chain but can also play a crucial role in helping contractors win tenders. Early collaboration at the pre-tender stage can reap real rewards. By using digital engineering technology, recommendations on project structures and construction phases, not to mention the ability to identify any potential challenges, can be ascertained.

3. Tackling the skills shortage

In November, data from the Office of National Statistics revealed that redundancies during the pandemic had resulted in the lowest number of people employed in the construction sector since 2013. However, with projects up-and-running again with renewed vigour, it’s anticipated that more positions will become available in the coming months. A construction sector that is innovative, collaborative, and forward-looking will be more attractive to new entrants.

Time for change

In response to evolving working practices in the industry, which have been further accelerated by the outbreak of Covid-19, leading international manufacturer and supplier of formwork, falsework, groundwork and safety systems, RMD Kwikform, has created LocusHUB; a ‘one-stop’ hub for all its digital innovations and resources. Available at locushub.rmdkwikform.com, it brings together all RMD Kwikform’s digital assets including apps, product videos, CAD resources and technical data.

Designed and developed to meet the changing needs of the construction industry, LocusHUB offers users an evolving library of digital tools to help optimise working processes and improve productivity levels. Tools on LocusHUB include LocusEye, RMD Kwikform’s innovative 3D visualisation software, which offers high-quality interactive 3D models of temporary work schemes. RMD Kwikform’s entire catalogue of material handling and guidance notes for its products is stored on LocusHUB, too.

It’s clear that now is the time for the construction industry to fully embrace digital technology and new ways of working to address evolving health and safety regulations, drive substantial operational improvements and maximise potential in the ‘new normal’.

Matt Wiseman is Divisional Digital Innovation Manager at RMD Kwikform, a leading global supplier of formwork, shoring and access solutions. With a diverse product range, designed to maximise safety, on-site effectiveness and lowest in use cost, matched with engineering excellence, RMD Kwikform provides customers with the most effective solution to get the job done.

For more information, please see: www.rmdkwikform.com

To find out more about LocusHUB from RMD Kwikform, please visit https://locushub.rmdkwikform.com

1 McKinsey & Company, ‘Rise of the platform era: The next chapter in construction technology’, https://www.mckinsey.com/industries/private-equity-and-principal-investors/our-insights/rise-of-the-platform-era-the-next-chapter-in-construction-technology

2 PwC, ‘Construction’s digital past and future: Where do we go from here?’ https://www.pwc.com/us/en/industries/capital-projects-infrastructure/library/construction-workforce-digitalization.html