Is Net Zero an achievable target?

Insulating the future

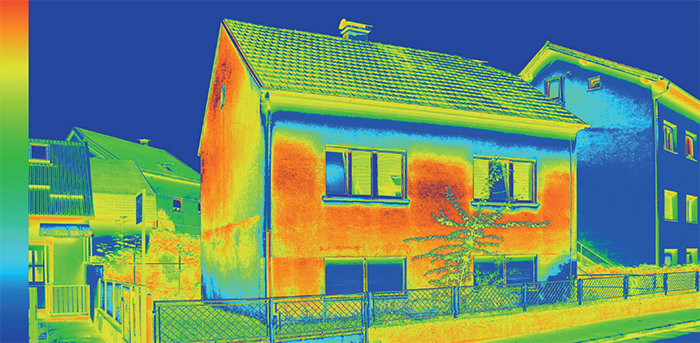

Building for the future with legacy in mind is a major challenge for the whole construction sector. Faced with the ambitious Net Zero target for 2050, the sensible approach is to make the right choices that not only meet but exceed regulatory targets for thermal efficiency without compromising on materials. Simon Storer, Chief Executive of the IMA, explains why a fabric-first approach to design is the way forward and a key measure to reducing heat loss, improving energy consumption, and cutting carbon emissions.

The role of PIR and PUR insulation in achieving energy efficient buildings and a sustainable future cannot not be underplayed. Good insulation is essential if homes and buildings in the UK are to become more energy efficient and sustainable and off-set some of the increasing energy costs and climate change conditions. The fabric-first approach to energy efficiency prioritises insulation within the building envelope, significantly restricting air leakage, which in turn prevents heat loss.

Using PIR insulation with high thermal efficiency will make a big difference between a building’s success or failure and is one of the simplest and most cost-effective ways to reduce energy demand and cut CO2. The thermal performance of a building envelope makes a significant contribution to reducing the overall building energy usage – so tighter U-values in walls, floors and roofs will help to deliver the standards required.

With lambda values as low as 0.021 W/ mK, PIR insulation is available as boards, blocks and composite panels, and PUR as spray and cavity injected insulation. Performance can be achieved with products that are thinner than many other commonly used insulants. In short, designers can achieve the highest insulation values from the minimum thickness of material, which in turn maximises floor space. PIR insulation products are widely used on residential, commercial and refurbishment projects because of their exceptional insulating properties, high strength and light weight.

With lambda values as low as 0.021 W/ mK, PIR insulation is available as boards, blocks and composite panels, and PUR as spray and cavity injected insulation. Performance can be achieved with products that are thinner than many other commonly used insulants. In short, designers can achieve the highest insulation values from the minimum thickness of material, which in turn maximises floor space. PIR insulation products are widely used on residential, commercial and refurbishment projects because of their exceptional insulating properties, high strength and light weight.

Build back better

Whilst many more affordable homes need to be built to an overall higher performance level to reduce costs and emissions, all homes need to be finished to a much better build quality. We must reduce or better still eliminate the ‘performance gap’ between design performance and what is built.

This is why competency in installation is vital, because when a high performing product such as PIR/PUR is not installed correctly, the thermal performance will not be maximised and the full benefits not realised. Contractors need to make sure that not only the levels of site supervision are of a good standard, but the manufacturer’s installation instructions are followed to avoid issues around potential cold thermal bridges and awkward details. Once the high-quality building fabric has been completed there should be no need to worry about it over the life of the building.

Getting it right first time

If the housing stock is to meet long-term performance standards, then we must have more thermally-efficient building envelopes, which in turn will result in improved comfort for occupants. Getting the fabric of the building properly insulated should always be the starting point. It is a fundamental step towards achieving the net-zero target as well as compliance with the energy performance requirements of the revised Building Regulations Part L.

By considering the fabric from the outset of a project, it is estimated to cost just one-fifth of the total cost of retrofitting to the same quality and standard at a later date. Homes should be built that solve today’s challenges and provide long term solutions, as it would be scandalous if homes being built today become the homes in 2050 that need to be retrofitted.

Changes to Part L Regulations

Within the new Part L requirements of the building regulations, all new homes will be expected to produce 31 percent less carbon emissions through a combination of fabric improvements, low carbon heating technologies and PV panels. This 31 percent reduction is the first step, but by 2025, new housing will be expected to produce 75-80 percent less carbon emissions compared to current standards. Achieving higher Fabric Energy Efficiency Standards (FEES) in specifications will be crucial for housebuilders in order to pass SAP and comply with Part L. Looking ahead to the Future Homes Standard in 2025, boilers might be replaced with air source heat pumps or some other low carbon technology, but the fabric targets of the building are expected to remain. As we have said, getting the fabric right in the first instance, is not only a sustainable approach but also a tried-and-tested way of limiting heat loss within the building.

The enormous challenge of achieving a Net Zero carbon-built environment must be woven into what many are now saying must be a ‘green economic recovery.’ Good insulation clearly has a role to play and by taking the fabric-first approach, specifiers will be taking the direct route to achieving the Net Zero target.

Insulation Manufacturers Association

www.insulationmanufacturers.org.uk

Insulation Manufacturers Association (IMA) is the Trade Association that represents both the Polyisocyanurate (PIR) and Polyurethane (PUR) insulation industry in the UK. Its members manufacture rigid insulation that provides around 40 percent of the total thermal insulation market in the UK. IMA’s membership comprises all of the major companies in the industry, including manufacturers of finished PIR and PUR insulation products, as well as suppliers of raw materials and associated services.