Load Deck Systems

With a solution that rivals its competitors’, Load Deck Systems is well placed to serve an industry that is becoming increasingly health and safety conscious

Safety should always be first

With a solution that rivals its competitors’, Load Deck Systems is well placed to serve an industry that is becoming increasingly health and safety conscious

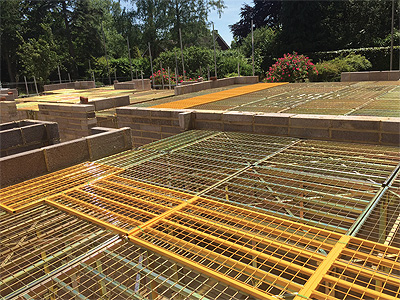

Entering the market in 2006 when Gaz Baines, who had amassed a wealth of experience designing crash deck solutions, decided he could make something better on his own, Load Deck Systems Limited (LDS) is part of an ongoing safety revolution in the construction industry. “The company designs and manufactures a modular system that can be used as a brick layer’s trestle and a crash deck solution,” explains General Manager, Ty Wilson. As a replacement for internal scaffolding (bird cages or air bags) the system can be built inside a building once there are foundations laid and ensures that any workers such as builders, electricians, plumbers cannot fall off. The rights to the G-Deck system are owned by 3G Metal Fabrication Ltd, but LDS acts as the sales vehicle driving the solution into the market.

“The system essentially eliminates time and costs on relying on other external companies to provide internal scaffolding solutions as can be erected with ease,” continues Ty. “It was designed with very few components, so is very easy to get to grips with and can be put up by a customer’s own team.” The concept of an internal crash deck is not a new one and is part of an ongoing drive with legislations changing, to increase on-site safety in the construction industry. However, as Ty highlights, LDS’ G-Deck system has a number of benefits that put the company ahead of its competitors. “We feel our system is the strongest available and is still made by hand to make sure the core strength is retained,” he says. “It is then dipped in a special zinc coating that gives it a very hard wearing surface, which compared to some of our competitors’, gives it superior longevity. In addition to this, as a manufacturing company, we are able to cater for any bespoke requirements.”

Such is the ease of constructing the modular system, Ty points out that a team can put together the decking at a rate of about 50 square metres every 30 minutes. “We only actually demonstrate with four square metres and by two square metres people have got it already, it’s that simple,” he notes. “The proof is in the pudding – once people have had it on site and are putting bricks and materials on it, we are getting a lot of excellent feedback from people who feel a lot more comfortable up at heights, this in turn speeds up work.”

Return-on-investment is relatively quick, so it is pretty clear that the G-Deck system provides a number of cost advantages over using traditional, internal scaffolding systems, but it is its safety benefits where it really excels. “The changes in health and safety regulations are causing everybody to become more conscious because of this, which has a significant effect on us. Despite company directors and H&S officials becoming more aware of people on building sites, unfortunately you still hear about accidents where people are falling off and being seriously injured,” says Ty. “The G-Deck solution is all about prevention – the only height you can fall is the height of your body.”

directors and H&S officials becoming more aware of people on building sites, unfortunately you still hear about accidents where people are falling off and being seriously injured,” says Ty. “The G-Deck solution is all about prevention – the only height you can fall is the height of your body.”

With a brand and a solution still relatively early in its lifetime, LDS faces the challenge of educating the market to the cost and safety benefits offered by the G-Deck system and this is where its focus lies for the near future. So too is a continued commitment to investment, with a number of other developments in the pipeline. “There are also market challenges taking it into Europe,” explains Ty. “We have two factories, one in Leicester, which delivers to the UK market, and one in Poland, which manufactures for Europe and therefore reduces freight costs.”

In general the next 12 months will very much be focused on developing the company in the UK and making sure it covers this market in the best way possible. “We are looking to team up with resellers and hire companies,” notes Ty. “We currently have sellers who also rent the decking out to smaller builders who will only need it for a certain period.” Longer term, the company will be looking at extending its hold out across Europe and possibly globally once this has been achieved.

Ty has a positive outlook on the future of LDS and also has a lot of confidence in the product. “We’re doing a UK road show at the moment where we go to sites and erect a demonstration so that people can have a look, so if anybody is interested we’re happy to visit them,” he concludes.

Load Deck Systems Ltd

Services: LDS Design and manufacture modular crash deck