New White Paper on Understanding PV and Fire Risk on Flat Roofs

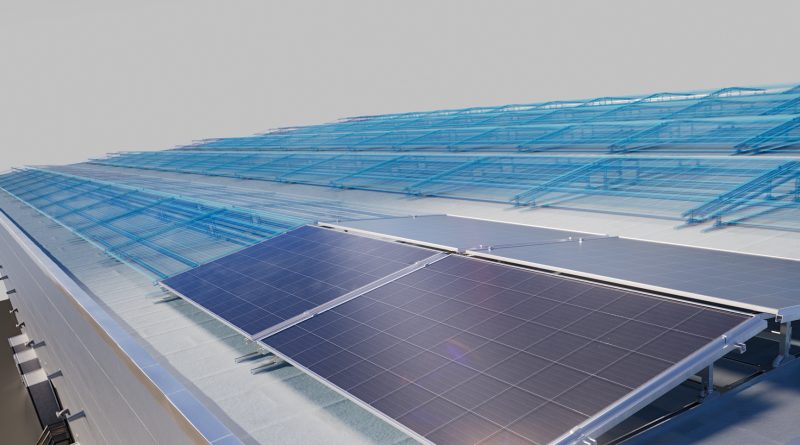

Harnessing the power of solar energy is a key step in tackling climate change, but as more PV systems are being installed on commercial rooftops across the world, an increase in the incidence of fires has been noted. Whilst these are generally not caused by the PV panels themselves, their presence can affect how a fire may develop, and to date there has been little research on how the building materials used underneath a rooftop array may perform.

Because this is an area that is not currently well regulated, and the scale of the issue is not well understood, some insurance companies are now preferring the use of non-combustible/Euroclass A1 or A2 materials, including insulation, under PV panels installed on flat roofs. However, this may lead to unnecessary over-specification, excluding proven products that can bring other benefits to the building. So what evidence is there of additional risks in using standard flat roof constructions?

Testing Flat Roof Systems

To start to fill this knowledge gap, two rounds of comparative tests were conducted in 2020/21 by independent fire safety consultants, Efectis, to understand the relative fire performance of two flat roof build ups. One insulated with a Euroclass A1 rated dual density synthetic rock mineral fibre insulation product, recommended for use under PV systems, and one with an FM Approved PIR insulation product. Both insulation products were sourced from the Dutch market.

The scenario tested was of back-to-back roof mounted PV panels to reflect the most commonly used arrangement in Northern and Western Europe, where roof mounted panels are arranged in an alternating East/West-facing configuration to make the most of the available sunlight. Whilst the test results are specific to the flat roof and PV products and configurations that were tested and the circumstances of those tests, in both rounds of tests there was no significant difference between the extent of horizontal fire spread, which was very limited beyond the perimeter of the PV array in all cases.

A Comparative Look at Insulation Performance

With the build-ups insulated with the FM Approved PIR, roof deck temperatures peaked at under 40°C at approximately the same time as the visible roof fire self-extinguished, with no evidence of localised continuing combustion. The damage to the 100 mm thick insulation (charring through to discolouration) did not reach the level of the deck anywhere on the rig.

With the build-ups insulated with the rock mineral fibre, after the visible fire had stopped, ongoing smouldering combustion appeared to have occurred. For instance, in one of the two tests, temperatures on the underside of the insulation reached 200°C in one thermocouple, some time after the visible roof fire self-extinguished, before dropping. In places the damage to the insulation (binder loss) penetrated its full 180mm thickness and reached the level of the metal roof deck.

As the market for PV installations evolves and grows, it is crucial to understand the balance of risks involved, and to allow designers access to the tools and materials they need to make buildings more energy efficient, without unnecessary constraints.

Full details of the testing can be found in a Kingspan Insulation white paper, which can be downloaded here.